Inspired from the Diatom exoskeleton porous architectures, siliceous self-standing porous monoliths Si(HIPE) (High Internal Phase Emulsion) bearing multiscale porosity have been developed while coupling sol-gel chemistry and physical chemistry of complex fluids (lyotrope mesophases and emulsion). These porous monoliths offer accessible surface area of around 1,000 m2/g and a macroporous volume falling around 9 cm3/g.

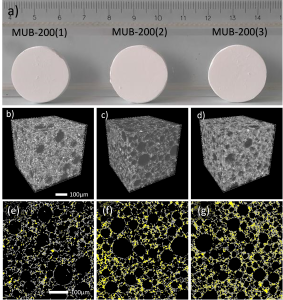

Recently, syntheses of mixed-oxides MOx-Si(HIPE) (M= Cu, Fe, Ce, Ni, Mn, Nb, Ta,Ti, Y, W, Co and so forth..)1,2 harvest highly efficient heterogeneous monolithic self-standing catalysts towards environmental catalysis or green chemistry as for instance: CO thermo-oxidation toward CO2,3,4 while limiting the use of noble metals, acylation and alkylation without the need of super acids while being additionally co-solvent free;5 photo-assisted VOCs removal and photo-induced degradation while acting in volume6 minimizing thus dramatically the foot print penalty. These mixed-oxides (binary, ternary or even quaternary systems), shaped over several length scales are labelled MUB (MUB acronym standing for “Materials of the University of Bordeaux”) Fig. 1, are indeed offering several advantages when compared with traditional heterogeneous catalysts:

– Easily shaped at high scale, induced by the sol-gel process in use

– Non flowable, as obtained in monolithic sate where final geometries can be tuned on demand (rods, disks, columns, beads……..)

– Active sites are accessible at ease, while by-passing both the use of a first activation step to cancel the Laplace pressure and high molecular hindrance

– Mass transport optimized through the macroporosity where the pressure drop is minimized as far as it can be when operated under constant and continuous flux

– Photonic transport optimized in volume minimizing thus foot print penalty (Mie scattering effect)

– Low Fick diffusion kinetic circumvented with the Taylor-Aris dispersive behavior occurring at the interfaces between the macroscopic walls and convecting/advecting fluids

– Catalysts regenerated at ease through a simple thermal or washing treatment

– High stability regarding the temperature and the solvents in use

– Cost being somehow reasonable and extendable at the industrial scale

Figure 1.a) Some SiO2-TiO2 (MUB 200 series) catalysts being photo-active in volume where the TiO2 content is increasing from the left to the right. b-d) 3D-microtomography reconstructions of the MUB-(200) series where the TiO2 content is increasing from the left to the right. Picture reformatted from the reference (6).

Beyond the CRPP, several laboratories from the Aquitaine region are already involved in this research topic: ISM et ICMCB (Bordeaux), IPREM et DMEX (Pau), IC2MP (Poitiers), RESCOLL (SA, Pessac). Native collaborations are evolving in France, L2CM (Nancy), IS2M (Mulhouse), LCMC-P (Paris), ICGM (Montpellier), IPCMS (Strasbourg). This scientific and human adventure is only at his nucleation step while several works are undergoing while encompassing molecular chemistry, engineering processes, as well as circular and sustainable chemistry.

Funding: The Nouvelle-Aquitaine region council, the GPR « Post-Petroleum Materials –PPM », the CNRS and the University of Bordeaux are thanked for their financial supports contributing thereby to this project emergence.

References

[1] Métallo-oxydes nanoparticulaires monolithiques à porosité multi-échelles. I. Ly and R. Backov. French patent 2020, deposit number FR20- 58457. International Extension 2021 PCT/FR2021/EP075529.

[2] Procédé de préparation d’un matériau sous la forme d’un monolithe de silice poreux comprenant des nanoparticules d’oxyde de titane, ledit matériau et ses applications. E. Layan, I. Ly, T. Toupance, T. Pigot, M. Le Bechec and R. Backov. French patent 2021, deposit number FR21-13537.

[3] Designing CuO-SiO2 and Cu°-SiO2 Monolithic Ceramics Bearing Hierarchical Porosity towards Robust and Cycling CO Oxidation Properties. A. Vardon, H. Labarrère, N. Chanut, F. Nallet, F.Weill, C. Labrugère-Sarroste, J.-L. Bobet, I. Ly, F. Epron, C. Especel and R. Backov. Chem. Mater., 2023, 35, 228.

[4] Binary CoOx-SiO2 Porous Nanostructures for Catalytic CO Oxidation. I. Ly, A. Vardon, N.Chanut, F. Nallet, R. J.-M. Pellenq, M. Rouzières, R. Clérac, J. Akil, F. Epron, C. Especel and R. Backov. ACS Applied Nano Materials, 2022, 5, 7331.

[5] Design of Binary Nb2O5-SiO2 Self-Standing Monoliths Bearing Hierarchical Porosity and their Efficient Friedel-Crafts Alkylation/Acylation Catalytic Properties. I. Ly, E. Layan, E. Pichea, N. Chanut, F. Nallet, A. Bentaleb, M.-A. Dourges, R.J. Pellenq, E. A. Hillard, T. Toupance, F. Dole, F. Louërat and R. Backov. ACS Applied Materials & Interfaces, 2022, 14, 13305.

[6] TiO2-SiO2 Self-Standing Materials bearing Hierarchical Porosity: MUB-200(x) Series towards 3D-Efficient VOCs Photo-abatement Properties. E. Layan, J. Gupta, I. Ly, F. Nallet, E. Laurichesse, R.A.L. Vallée, J.-L. Blin, B. Lebeau, F. Louërat, M. Le Bechec, P. Moonen, T. Toupance, T. Pigot and R. Backov. Langmuir, 2023, 39, 3871.